INSTRUMENT PRODUCT / RIGAKU RIGAKU

All Products

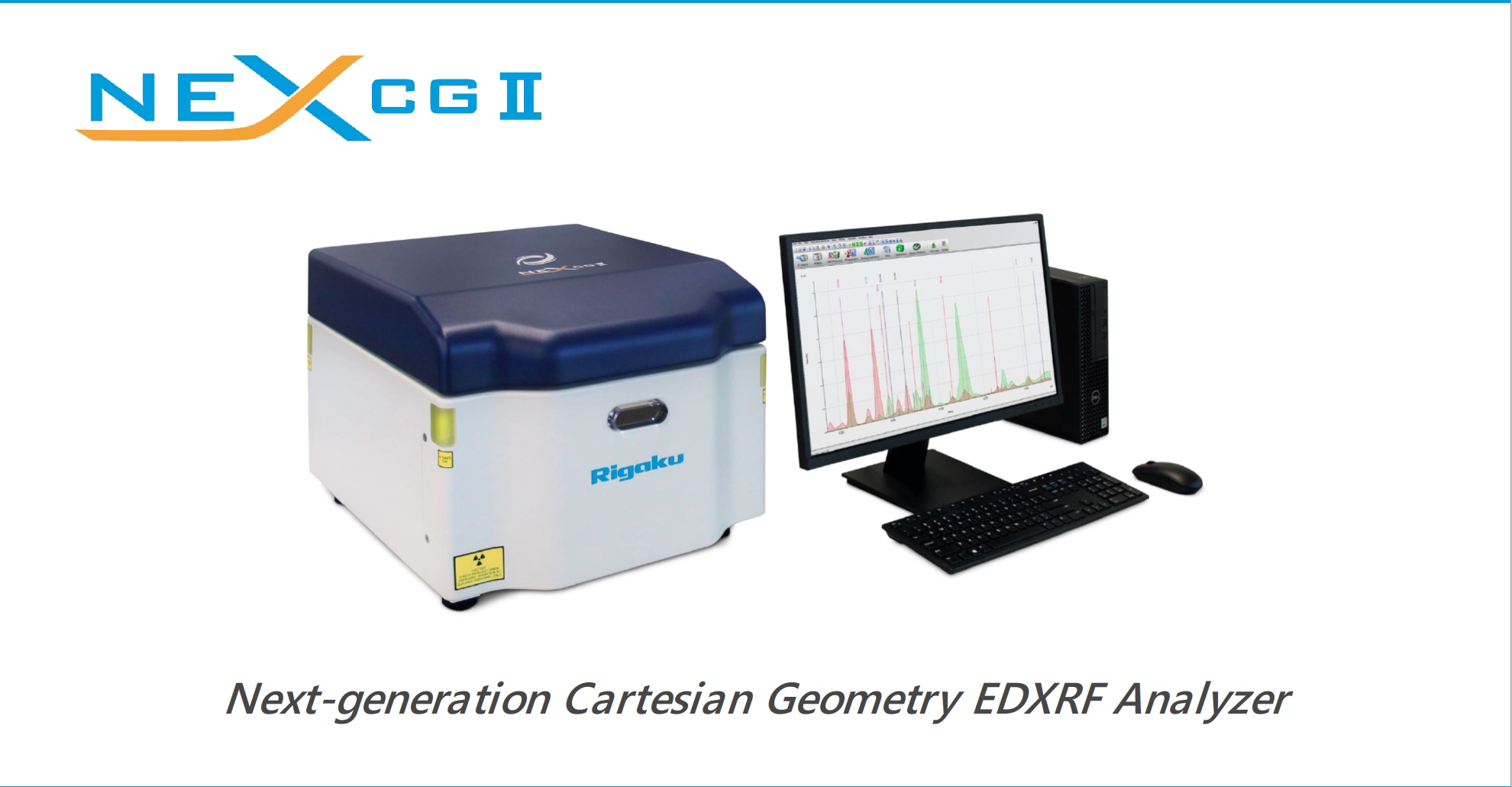

Rigaku EDXRF

Rigaku's ART division specializes in X-ray fluorescence (XRF) spectrometers employing energy dispersive detectors (EDXRF). XRF is an X-ray spectrometric technique for elemental analysis of a wide variety of materials. Other phrases for XRF instruments include: XRF analyzer, XRF spectrometer, XRF analysis, X-ray fluorescence analyzer and x-ray fluorescence spectrometry. Typical uses of EDXRF include the analysis of petroleum oils and fuel, plastic, rubber and textiles, pharmaceutical products, foodstuffs, cosmetics and body care products, fertilizers, geological materials, mining feeds, slags and tails, cement, heat-resistant materials, glass, ceramics, catalysts, wafers; the determination of coatings on paper, film, polyester; metals and alloys, glass and plastic; forensics; multi-layer thin films on silicon wafers, photovoltaics and rotating storage media as well as pollution monitoring of solid waste, effluent, cleaning fluids, pools and filters. In addition, X-ray Transmission (XRT) process gauges are employed to measure sulfur (S) in crude oil and marine bunker fuel.

XRF and EDXRF spectrometers are the elemental analysis tool of choice, for many applications, in that they are smaller, simpler in design and cost less to operate than other technologies like inductively coupled plasma optical emission spectroscopy (ICP-OES) and atomic absorption (AA) or atomic fluorescence (AF) spectroscopy. Examples of some common EDXRF applications are: Cement and raw meal: sulfur, iron, calcium, silicon, aluminum, magnesium, etc; Kaolin clay: titanium, iron, aluminum, silicon, etc; Granular catalysts: palladium, platinum, rhodium, ruthenium, etc; Ores: copper, tin, gold, silver, etc; Cement and mortar fillers: sulfur in ash.

Other examples of common EDXRF applications include: Gasoline, diesel and RFG: sulfur, manganese, lead, etc; Residual gas oils: sulfur, chlorine, vanadium, nickel, etc; Secondary oil: chlorine, etc; Kerosine, naphtha: sulfur, etc; Crude oil and bunker fuels: sulfur, vanadium, nickel, etc; Plating, pickling & pre-treatment baths: gold, copper, rhodium, platinum, nickel, sulfates, phosphates, chlorides, etc; Acetic acid: magnesium, cobalt and bromine; Terephthalic acid (TPA): cobalt, manganese, iron, etc; Dimethyl terephthalate (DMT): heavy metals; PVC copolymer solutions: chlorine; Photographic emulsion: silver; Clay: metals and non-metals; Waste and effluent streams: RCRA metals, chlorides, phosphates, etc. Additionally, EDXRF and XRF are employed to quantify atomic elements in: Food, pet food and other animal feed: potassium, phosphorus and chlorine; Cosmetics: zinc, titanium, calcium, manganese, iron, silicon, phosphorus, sulfur, aluminum, and sodium; Wood treatment: CCA, Penta, ACQ, ACZA, phosphorus-based fire retardants, copper naphthanate, zinc napthanate, TBTO, IPBC and combinations of these; Antacids: calcium; and Toothpaste: phosphorus and tin.

MSI Technologiesประเทศไทย

MSI Technologiesประเทศไทย

140/13 Moo 12, Kingkaew Rd., T.Rachathewa, A. Bangplee, Samutprakarn 10540 Thailand.

MSI Established in early 2003 and Incorporated in Jan 2004, MSITECH is a young but leading supplier of Scientific Instruments, Heavy Machinery/Spare Parts and various Consumable for the Metal Industries.

Copyright © 2024-2025by

BRUKER

BRUKER

RIGAKU

RIGAKU

Foundry Consumable

Foundry Consumable